LEDs are now commonplace in our industry and can offer a lot of value in terms of extended life and energy savings. Unfortunately the industry is riddled with misinformation and misleading statements that can lead to a frustrated sign maker and a disappointed customer. We will take a look at some of the information that is out there and what the data actually means.

First, we need to understand the key drivers that impact performance of a light source and compare those to the terms commonly used in LED specifications. Finally, we need to understand how that translates to a return on investment (ROI) for the customer for applications that LEDs work. Using this data, we will look at traditional technologies like neon and fluorescent lamps and understand applications that do and don’t make for LED light sources.

Clarifying Terms

Performance can encompass a range of items. Below are some key performance terms that are important to understand.

Lifetime—A measure of how long the light source actually lasts. Here there are a few things to consider. First, LEDs do not burn out, but typically will degrade over a period of time. In “LED terms” what is often quoted is the L70 life. This is the life in which 30 percent of the usable life is lost and is considered the end life.

However, it should be noted that depending upon the initial output of the LED, a sign may still be commercially acceptable beyond that point. It really depends upon what is around the sign. It should be noted the lifetime for fluorescents is measured in a completely different manner.

The lifetime of a fluorescent lamp is determined by taking a set of them at room temperature and the point at which 50 percent of the lamps burn out is considered the specified life. It should be also noted that fluorescent lamps dim as well over time. Often specified is the “mean lumens” as well as the “initial lumens.”

Neon on the other hand can last for years or decades if processed properly. Since each piece is made custom and by a different tube bender, lifetimes are more dependent on the quality of the fabrication than anything else.

Lumens (LM)—A measure of total light output. For tubes the light emits uniformly in all directions. For LEDs the light is directional and can depend on the beam angle. This means that LEDs with a wider beam angle will deliver less light to the face of a sign versus a narrower beam LED at the same total lumens. It also means that for single-sided signs that LEDs can deliver more light to the sign face (LUX) than a non-directional light source.

LUX—The amount of light per unit area (LM/meter2). This is the amount of light that is measured across a sign face.

Efficiency—The amount of light emitted per unit of power, often expressed as LM/Watt. Light sources with higher efficiency require less power to put out a certain amount of light. Keep in mind that the luminous efficiency is best for comparing white sources of light, as colored LEDs are fairly monochromatic and should only be used to compare LEDs that are the same wavelength.

Ingress Protection (IP rating)—IP ratings are a two number system in which the first number references the products resistance to dust and the second is the products resistance to water. For example, an IP66 rated product is rated as dust tight and protected against powerful water jet. IP67 and 68 products are rated to be submerged in water.

Color Temperature (CCT)—CCT is a term used for white LEDs to determine how warm or cool the LEDs are and is expressed in degrees Kevin (K). Lower values like 3000K indicate a soft incandescent light color. Bluer tone LEDs are usually above 7000K. The whitest part of the color spectrum that causes the least amount of color shift is between 5000-6000K.

LM 79/80 Testing—Validated third-party tests that measure the change in luminous output and color temperature over a minimum of 6,000 hours of testing.

All of the above terms are used regularly when reading LED, neon and fluorescent specification sheets. The key is to understand how much light you need to create a certain LUX at the sign face and then understand what kind of reasonable lifetime you can expect.

Common LED Misconceptions

Let’s look first at some misconceptions about LEDs that surround and incorporate the terms we reviewed above.

LEDs last 100,000 hours—This is likely not to happen. First, in order to truly know the output of an LED after 100,000 hours, you actually have to test it that long. This would take 11.5 years of continuous operation to determine.

Some manufacturers extrapolate the light lost after the 6,000-hour LM80 test. “This test specifically states that it is not designed to make extrapolations,” says J.P. Garcia, who is in engineering services with Principal LED. “Our Fusion LED actually went up 0.4 percent after 6,000 hours of LM80 testing; however, we would not extrapolate this to mean that the LED output will increase, nor say the LEDs will last forever. What we can say is that our performance exceeds those under which the same testing was performed.”

It is also important to note, that this test is performed at room temperature. Elevated temperatures, (i.e. a sign cabinet in the middle of Arizona) will cause precipitous degradation in the life of the LEDs, especially if the LED is being pushed or driven up to its thermal limits.

The point is that L70 values is at best guess based upon extrapolating from a third-party test or in-house testing. Therefore, it is critical to see actual test data to perform a valid head-to-head comparison.

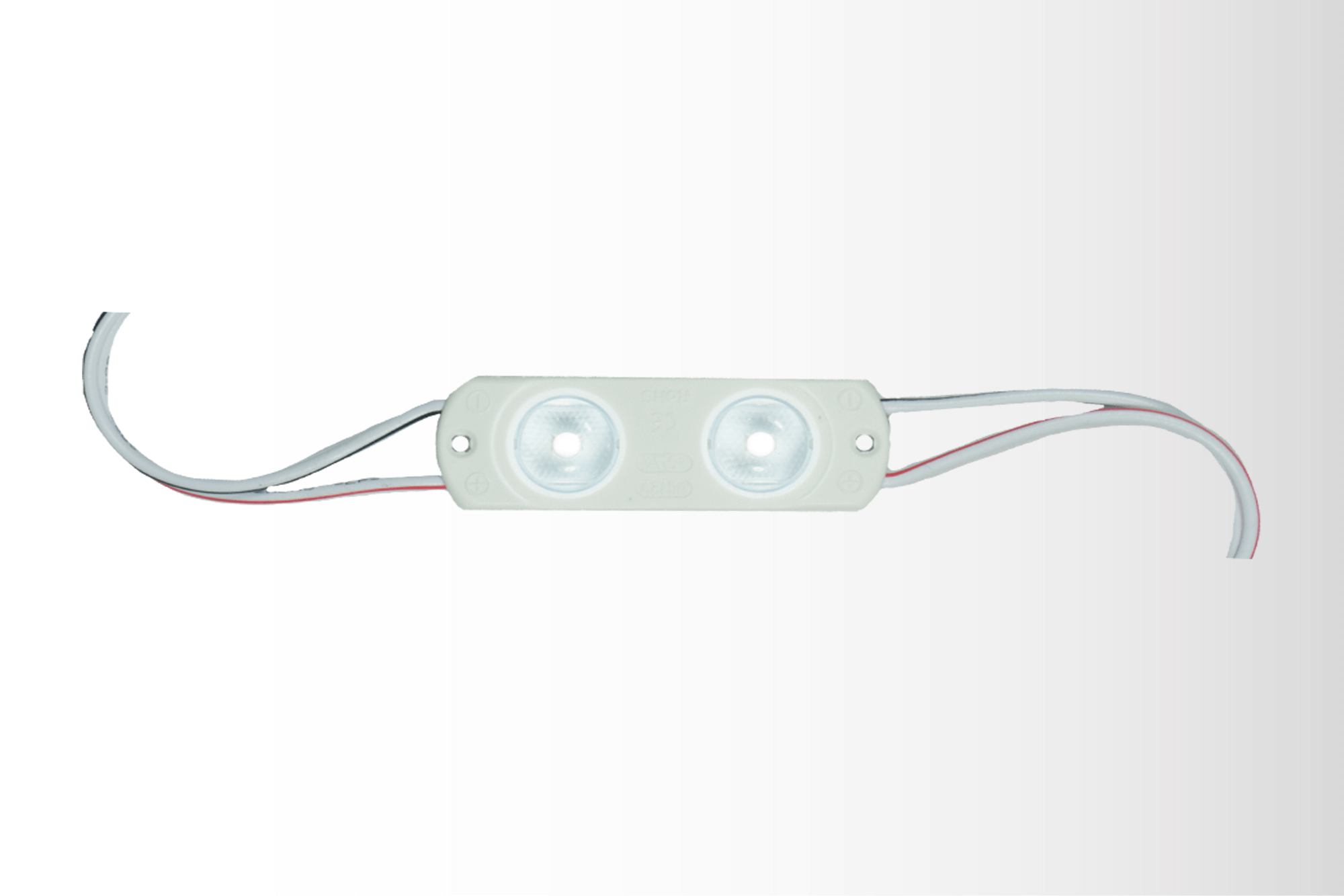

LEDs are maintenance free—This is completely untrue. While they may require less maintenance than their fluorescent counterparts, they still will dim and they also have a power supply that can fail over time. In addition, they still can attract dust and debris on the surface, which will require cleaning to make sure the light can escape from the fixture or module.

Our modules are UL-rated for wet locations—Keep in mind that UL is a safety rating, not performance certification. If the LED module is 15V DC or less it will automatically be wet rated, as it is considered inherently safe. More important is IP rating. However, if the modules are completely over-molded and sealed, it is important to get the LM80 test results.

There is a tradeoff between sealing the LEDs (which limits the ability for heat to escape and thus lowering the life) and not completely sealing, which results in lowered protection from corrosion due to water exposure.

These modules are cool to the touch, so they will last longer—This is one I hear all the time. Depending on the chip type and size, LEDs can be severely overdriven without feeling any external heat. In addition, if the LED is encased in a plastic housing, it acts like a Styrofoam cooler—it will feel room temperature on the outside, but may be burning up inside. The point is to ask the manufacturer for their data and warranty statement.

LEDs outperform fluorescent lamps—This is only partially true. Certainly LEDs are more efficient and longer lasting than existing T-12s; however, Voltarc Technologies, Inc. currently sells its Trilight Max, which boasts a T-12 and T-8 with 50,000 and 60,000 hours of life respectively and 25-40 percent improved efficiency. So don’t expect the fluorescent manufacturers to turn over their market share right away.

Bottom Line Considerations

So, based upon this information, let’s wrap some financials around this. At the end of the day, customers are looking for a return on their investment. In today’s economy, most folks will tell you that if they can’t get their money back in three years or less, why bother.

For the sign industry, I began looking at ROIs using various LEDs to replace T12 lamps in a range of sign cabinets. As it turns out there were three key drivers: the up-front cost of the LED system, the maintenance savings, and the energy savings (in that order). New construction inherently offers better ROIs than retrofits because of the labor cost to perform the retrofit. For retrofit applications, I recommend performing the retrofit at the time the existing lamps need to be replaced (i.e. when the customer is already incurring the cost of a service call).

Most of the LED systems I have evaluated as fluorescent replacements are about T-12 output and offer the same energy savings (roughly 50 percent). Those systems that are in the $20 per square foot range for a double-sided sign generally offer ROIs in the 30-48 month range. As we see system prices come down to the $10 per square foot, retrofitting will become more viable—even for smaller signs in easy-to-service areas. So while it is true that LEDs are a good choice to replace neon or fluorescent tubes in single-sided face-lit applications, most LED systems still create sticker shock for double-sided face-lit cabinets.

Neon is Unique

Stepping briefly aside from the ROI piece, let’s talk about neon for a moment. First, let me say that I love neon and I have a lot of respect for its historical and current presence in our industry. Neon creates a classic look and offers long life, and while there are some great LED border products that are out there, they tend to be expensive, and in my aesthetic judgment cannot truly create the “glow” of classic exposed neon.

Neon has several advantages over LEDs. One being that neon can create an outline that becomes the sign. It is also available in a range of colors and can create depth by being displayed off the sign or surface. Finally, multi-stroke exposed neon creates a classic look that is unique unto itself.

Conclusions

In summary, there is a lot of hype about LEDs, as well as misconceptions. Unfortunately, not all LEDs are made the same and there are no quick tests to determine if the manufacturer’s claims are true. The key is to use a reputable manufacturer that will stand behind their warranty claims. Remember a typical set of channel letters has maybe 100 feet of product. Sometimes, the difference to step up in quality can be as little as $0.50 per foot. $50 is a pretty good insurance policy to know you are putting out a quality product that will last. Finally, it’s important to understand where LEDs work best and where they don’t. Fluorescent lamps, neon, and LEDs are all lighting sources than have a place in our industry and there is not a one technology fits all solution.

This article was published in Sign & Digital Graphics magazine on June 26, 2014.