Despite uncertainty in the overall economy, LED industry trends show solid growth over the next few years. We are reaching the tipping point in the overall LED industry and according to LEDinsight, the global market penetration was estimated to reach 31% of the $82.1 billion dollar global lighting market by the end of 2015. Much of the growth will come from commercial applications ($26.7 billion) which include street lights, parking lot lights, tunnel lighting, LED billboards and illuminated signage. LED market penetration is expected to swell to 70% by 2020. Although illuminated signage only represents a small portion of the overall market, sign makers can stand to benefit from the growth, which will result in better quality, new technology, vertical integration, and lower manufacturing costs. Five specific trends occurring in the LED industry that may impact the illuminated sign industry are:

New Semiconductor Materials

Nobel Prize winner Shuji Nakamura has proposed a move from blue to violet LEDs. Nakamura’s violet LEDs put the gallium nitride on a base of some more gallium nitride rather than sapphire – called ‘GaN-on-GaN’. Not only do they offer better color rendering, they also open up the possibility for extended life and greater efficiency. Nakamura is not the only one developing advanced materials to push the envelope of LED efficiency. Current commercial LEDs are around 125 LM/W. Recently, Cree announced that they have developed an LED that achieved over 300 LM/W. These types of efficiencies ultimately mean brighter LED modules with longer run footages that use less power supplies.

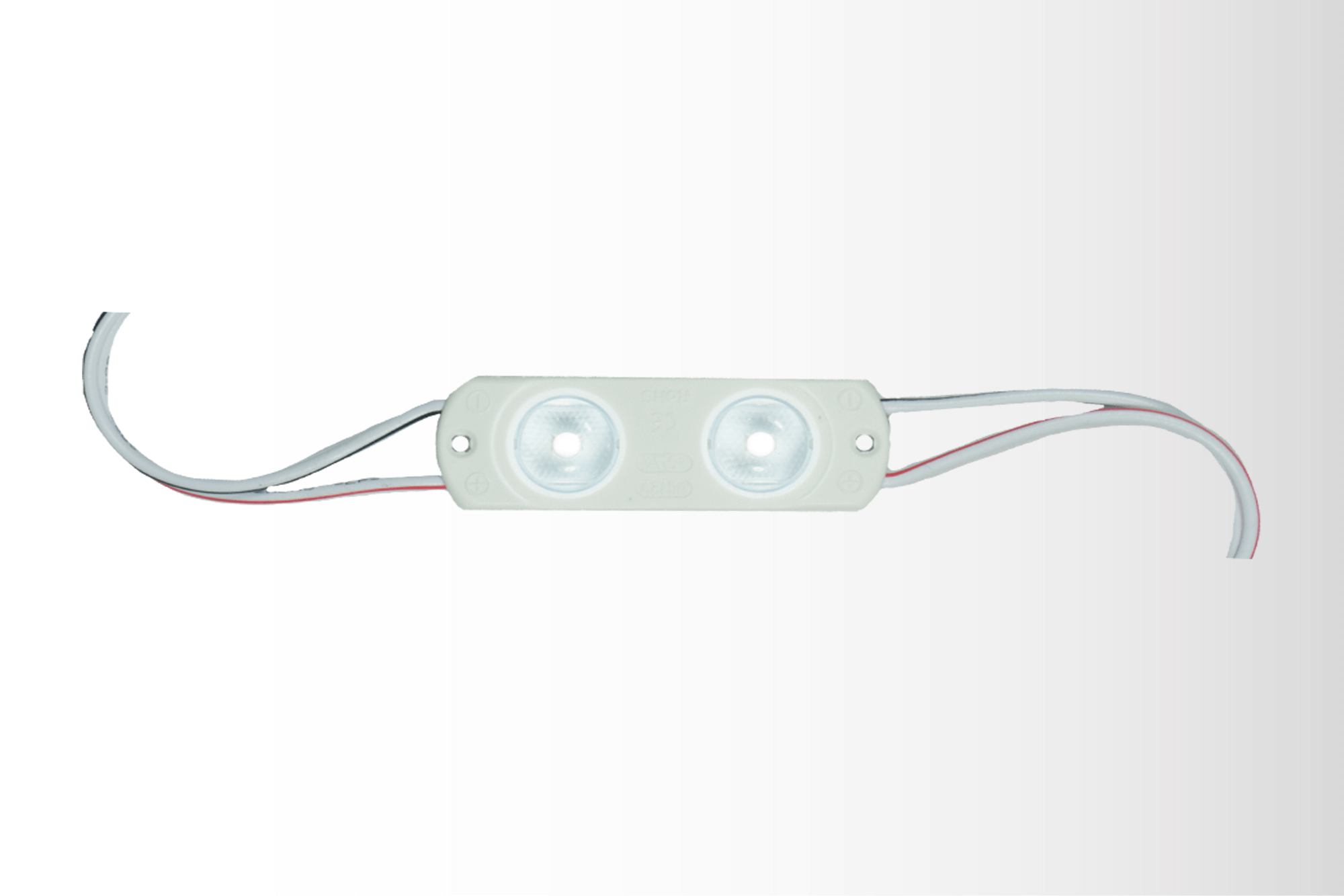

AC LEDs

Speaking of less power supplies, how about no power supplies at all? Chip and lamp makers have recently commercialized LEDs that are designed to operate directly off of AC current without the need of any rectifier circuits at all. At Principal LED we released “Fusion Powerline” the world’s first true AC LED channel letter module last year at ISA. I am personally a big believer in AC LED technology because it removes a key failure point (the power supply) in the LED sign system. Although the technology is relatively new, as the technology develops, I anticipate wider adoption of these systems, particularly in hard to access sign applications.

Chip Scale Packaging

CSP is a form of LED packaging that will continue to gain promise in coming years. CSPs take the concept of minimal packaging to the next level by incorporating interconnection pads on the bottom surface of the chip itself on a pitch that matches standard SMDs. This feature does away with the need for the chipmaker to add interposers, sub-mounts, or any other form of packaging. The obvious advantage of CSP LEDs is the technology significantly scales down the size of an LED package and are theoretically lower cost to manufacture. However, they also allow the phosphor to be coated on all five exposed sides of the chip, making it ideal to be coupled to optics lenses, keeping the color more consistent and even as the light leaves the optic – this can mean more even lighting in low profile illuminated signs.

Control Systems

Everything seems to be going wireless and lighting control is no exception. LEDs on the residential and commercial side are incorporating radio frequency communication and individual addressability through Wi-Fi. There are also a number of newer technologies like power-line communication that uses primary power lines to carry data to and from LED lights. These technologies allow control of the lighting from a tablet or cell phone. I expect this technology to creep into the sign market to allow end users to have control over all aspects of their lighting (including the sign).

Quality Improvements

We’ve all seen examples of poor-quality LED products that that make a sign look awful, all for the sake of “saving energy”. However as the Wild West days of the LED market has come to end, end users seem to be flocking back to quality across the commercial sector of the market. Although, there will be continued price pressures, especially in the more mature illuminated sign market, more sign manufacturers are trending back toward quality LED systems as well as commercial end users demand sign makers and LED manufacturers stand behind their reliability claims. Interestingly, the residential market seems to be trending the other way, as more manufactures are abandoning Energy Star and taking the “good enough” approach to satisfy the consumer’s insatiable appetite for low cost goods.

This article was published in the June 2016 issue of Sign & Digital Graphics magazine.