Choosing the Right System

Historically, backlighting was relegated to three primary forms of illumination: fluorescent lamps, metal halide or neon. With the wide variety of LED systems now available, sign makers have hundreds of choices to optimize signs of about any shape, size, or material. In fact, part of the problem is knowing which LED system to choose for a given sign application. In order to develop a strategy for choosing the appropriate LED backlighting, a sign maker needs to answer a few questions.

- What type of sign is going to be built?

- Where is the sign going to be used?

- What kind of manufacturing and installation capability do I have available?

The answers to these three questions can help drive making a good decision and having a solid product strategy when choosing the right LED backlighting solution.

Knowing the type of sign, its size, depth, and the desired lighting effects are probably the most important things to know in determining the right LED system.

Channel letters are pretty easy. Most likely, you will want to choose a “string-based” LED system. These are tried and true, offer the maximum flexibility and are relatively easy to install. Most sign companies have a particular module or manufacturer that they prefer. Sign modules come in a variety of forms—with or without optics, different colors, a range of outputs, etc.

General Rules and Considerations

However, there are some general rules that can be used to make sure you are not buying and installing too much or too little of a system. Your decision, of course, will depend upon the sign type and desired face material. Here are some things to think about:

Compensate for a Vinyl Face

If the sign face includes perforated vinyl, you may want to choose a brighter LED in order to compensate for the 50%+ light blockage as a result of the vinyl.

Beware of the Low-Cost Trap

Another consideration is cost. I have seen many sign makers take the approach where they just use the brightest, lowest-cost module they can find. Beware of this trap. For instance, if a 120 lumens-per-foot product (0.72W) system costs $2.50 per ft., and you can buy a 180 LM/ft. (1.2W) system for the same price, you may think – “Hey I am better off.” However, depending on the spacing you may still need the same number of modules and now instead of running 50 ft. per power supply, you can only fun 30 ft. Now you will need two power supplies instead of one, adding another $0.50 per ft. to your total cost when that level of brightness is not really required. It also adds labor and other costs to install and mount and wire the extra power supplies.

Consider a Universal System

Sign makers say they want to have one single module that is versatile enough to use for most channel letter applications. This certainly can simplify manufacturing and stock levels, but the tradeoff is flexibility. Principal LED has tried to address this unmet need with its Fusion Freedom module. This module is universal in that it has the ability to choose the desired output based on wiring and has a removable batwing optic, as well as a range of colored lenses that can be attached or removed to provide specialty colors and color temperatures of white.

According to Jeff Brazin, vice president of national accounts for Principal LED, “Our goal is to simplify the lives of our customers. Fusion Freedom allows sign makers to stock a single module that can be used in over 100 configurations with a simple lens change or based upon how the product is wired.”

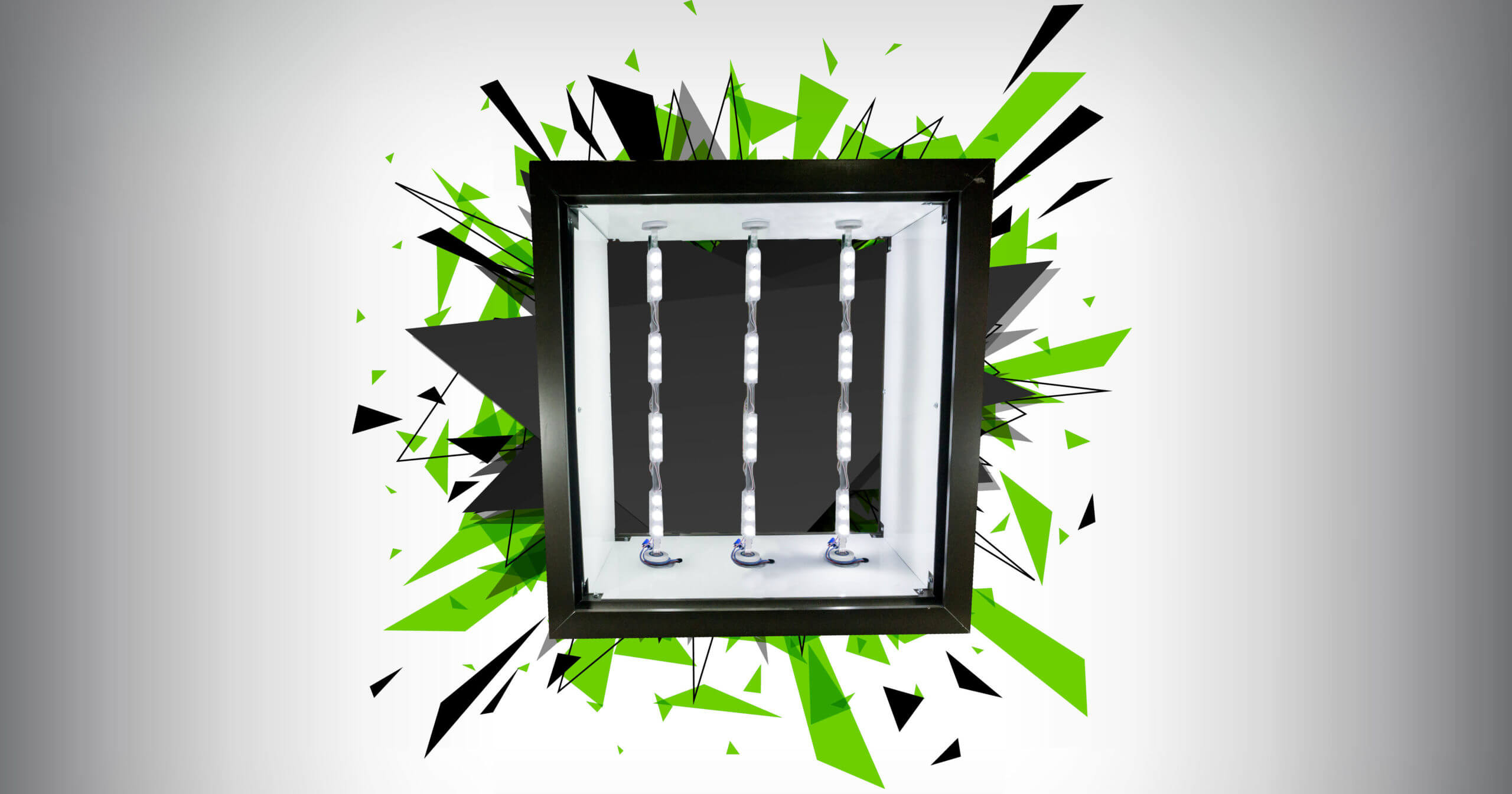

Sign Cabinet Modules

What about larger backlit applications like sign cabinets? While modules can do the job, they typically are laboriously time-consuming. In order to address this need a range of systems are available as fluorescent alternatives to illuminated sign boxes. In this instance, understanding the application and location of the sign is critical to your backlighting strategy.

For large outdoor illuminated signs, it is recommended to use a dedicated system. Many of the “new construction” systems are easy to assemble and install. For companies that are installation-based, many manufacturers offer LED systems that fit directly into T-12 sockets for sign retrofits and offer equal levels of illumination and even lighting on standard 12” centers.

While true LED cabinet lighting solutions are ramping up extremely well, we still see channel letter modules being used in very large signs by shops that have the misconception that the unit cost of string-based channel letter modules is cheaper than a dedicated cabinet sign solution.

Light Tapes

Light tapes are a new entrant into the sign market that can be a low-cost alternative that is easy to install for indoor sign cabinets. GE Lighting recently released its Tetra LED Tape, a flexible product that can be cut every two inches and is available with clamp-on jumper connectors; and they can be used in both sign cabinets and channel letter applications.

Principal LED offers Qwik Tape, another flexible tape system that utilizes a patented micro-pop rivet system that eliminates the need for soldering end wires and between ends of two reels. Qwik Tape also comes in Prime (175LM/ft.) and Prime HD (350LM/ft.) versions on long 164-foot rolls, reducing scrap and the end of rolls.

Side-Mounted Solutions

In some cases, cabinet or light box illumination is desired without the need for a baffle. While stick-based products often do the job, a number of manufacturers — including Principal LED (Street Fighter POD) — offer systems that can be mounted to the side (return) of the sign cabinet.

The modules use a focusing optic that narrows the bean angle parallel to the sign face, allowing even illumination in a range of sign boxes.

Pre-Plan, Choose Right

There is no question that the sign industry has undergone massive changes with the advent of LED technology over the past twenty years. There are a large number of LED options available today. Understanding the application, pre-planning, and then choosing the right product can speed up installation, improve performance, save money, and make for a happy customer.