No area of the electric sign industry has changed more in the last 10 years than sign backlighting. In the early 2000s, neon and T12 fluorescents dominated the sign industry—in channel letters and sign cabinets, respectively—as the backlighting sources of choice. LEDs represented an annoying 5 percent to 10 percent of the neon industry. In fact, at the time many industry “experts” felt that LEDs were just a flash in the pan. They were wrong.

By the end of 2007, LEDs had surpassed neon, and by the end of 2010 LED actually surpassed fluorescents in terms of total usage. Today I go into sign shops that exclusively use LEDs to illuminate their signage. I would venture to say that of the 15 percent to 20 percent of today’s signs that are made with neon, a big percentage of them are exposed versus backlit. This essentially leaves us with T8 fluorescent lamps and LEDs for sign backlighting.

Let’s face it, for today’s channel letter applications, LED systems are pretty much the default technology of choice—owing to their reduced labor costs and time for fabrication of the sign as well as the significant energy and maintenance savings over neon. LEDs also provide many choices today in terms of spacing, colors, and advanced optics, allowing sign makers to use them for just about any back-illuminated channel letter. However, when it comes to cabinet illumination the choice is not as straightforward.

Phasing Out the T12

Effective July 14, 2012, production of most T12 fluorescent lamps was phased out in commercial lighting applications, as mandated by the 2009 Department of Energy General Service Lamp legislation. Given these changes, along with the elimination of many T12 magnetic ballasts, LEDs and more energy efficient T8 lamps are the two primary options for sign retrofits and new sign construction.

The National Lighting Bureau (NLB) estimates that nearly 500 million T12 lamps are still installed in commercial, industrial, institutional and other non-residential lighting systems nationwide. Outdoor signage is currently exempt from the T12 fluorescent tube elimination mandate. Most of these 500 million lamps are in non-sign applications; however, the availability of T12 lamps will decrease and their market price will certainly increase over time.

Cabinet Sign Options

Educating customers on options is a key role for any sign maker. Table 1, using 2015 numbers, shows a typical ROI comparison between traditional T12 cabinet sign lighting versus long life T8 lamps and LEDs. Keep in mind this is just a typical comparison and can vary significantly on the LED side depending on the system. One important point to note is that regardless of the technology, the maintenance costs will represent the majority of the expense to the end user. If the sign is a retrofit, both systems will require you to remove the old ballast, rewire, and then replace with new ballasts (or power supplies).

For a single-sided cabinet sign, the payback between LED and T8 lamps is pretty negligible. In fact, for a newly constructed illuminated sign, there are additional savings in terms of reduced labor to punch the socket holes, etc., making LEDs a frontrunner for a single sided cabinet. LEDs can also be used to reduce the overall thickness of the cabinet, saving materials and creating a more sleek-style cabinet.

The other advantage for LEDs in single-sided cabinets is that the sign shop can use the same modules that it uses for their channel letters as they use for their cabinets. This reduces installation training as well as the number of materials that the shop has to keep in stock.

However, for double-sided cabinets, T8 lamps still have the upper hand on the price side. Voltarc Technologies, Inc. currently sells its Trilight Max T8, which uses a fully enclosed filament that lasts up to 60,000 hours, rivaling its LED counterpart. Fluorescents are naturally better for double-sided cabinets in general, as they emit light in a 360 emission pattern. LEDs, on the other hand, are directional and must be mounted in both directions in order to back-illuminate a double-sided sign.

For module LED strings, this requires the sign maker to either baffle the sign or mount the LEDs on each side of a piece of angle or square tubing, increasing labor costs.

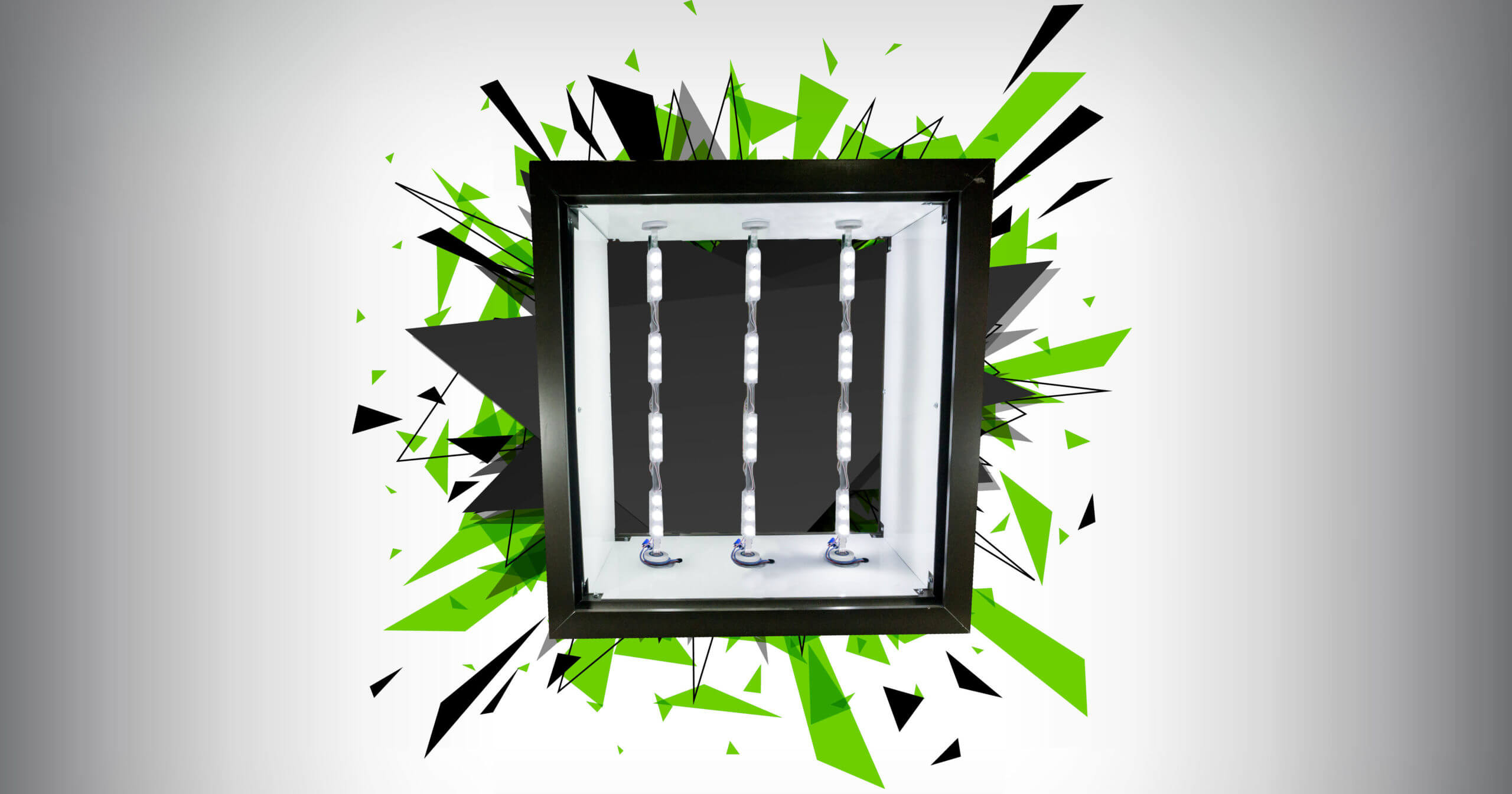

Many LED manufacturers sell specific systems for double-sided cabinets. Bitro Group (Lattice), Sloan LED (Sign Box II) and US LED (Tandem 2) cabinet products are easy to assemble and offer all of the mounting hardware to assemble the system in the shop or on site. Bothe GE (LineFit) and Principal LED (Qwik Stik) offer systems in which the LEDs can fit directly into an existing T12 socket, making retrofitting faster.

Another consideration for illuminating cabinets is if the power supplies must be mounted a long distance from the sign itself. This can add significant cost in large bundles of 8-12-gauge low voltage wire having to be used to get adequate power from the power supplies to the LEDs. Ventex is an established neon supplier that has leveraged its understanding of neon to offer a unique retrofit solution called VenBrite in which the LEDs are in a series arrangement, reducing the need for additional low voltage wire. The same LEDs used for channel letters can be mounted into the Snap Stick rail system and can operate on the existing neon GTO wire. By using the same modules, it is easy to create a consistent look when channel letters are next to the sign cabinet.

Backlighting Options

While there are a number of LED solutions, long life T8 lamps are still the technology of choice when it comes to back-illuminated cabinets (especially double sided). They can offer similar efficiencies and lifetimes as LEDs at a significantly lower price.

Keep in mind however, LEDs do have some additional advantages such as instant “on” and no flicker. They also perform better in cold weather and their output is not temperature dependent. They are also better for the environment due to the absence of mercury and have reduced breakage.

Even though LEDs and T8 lamps are about the same efficiency, the total power is usually reduced in LEDs since most of the light is directionally pointed to the face of the sign. The other consideration is lifetime, which can be a little confusing. Most fluorescent lamps rated hours are based upon mean failure—that is the typical amount of time before the lamp burns out. LEDs typically just dim over time and the rated life of an LED is typically the point at which it has dimmed 30 percent (considered the useful life). Therefore, an LED may actually last longer than an equivalent rated life T8.

One question I often get is, “What about the LED lamps that are like fluorescents and don’t need an external power supply?” Actually, they do have a power supply, which is a small open frame unit that fits inside the tube. These may be adequate for indoor applications; however, I do not recommend them for backlighting outdoor signage. These usually contain low-cost capacitors and other components that are a major point of failure, especially in extreme environmental conditions.

T8 vs. LED Considerations

There are a number of considerations when choosing between long-life T8s and LEDs and both technologies are excellent choices when backlighting cabinet signs. Although, I expect that long life T8 lamps will continue to be preferred for many illuminated cabinets. Long-life T8 lamps are definitely a great choice today, but that may change next year as lower-cost, higher-performing LEDs continue to come to market.

The final consideration when choosing an illumination source is the shape and structure of the sign itself. Face material and color, amount of graphics, and distance of the light source from the face are all technical considerations when choosing the light source for a backlit sign. For example, if the sign has full-color graphics it is important to choose an illumination source with a high color-rendering index (CRI) to provide “true” colors in both the red and blue parts of the image. Pragmatic considerations such as depth to the face are also important.

I have seen many cases where the sign face has been changed on an illuminated sign from a vacuum-formed face to a flat face, which resulted in striping of the fluorescent lamps. Whether it be channel letters or cabinets, I have also seen cases where the sign maker thought going to a thinner sign would save materials and be less expensive, only to find out they had to double the amount of LEDs to make the sign illuminate evenly. Most manufacturers have guidelines online or provide free layout services to help ensure the backlighting is installed to produce even illumination. If you are not sure, take the time to check with the manufacturer bidding the sign and certainly before fabrication or doing an on-site retrofit.

The Good News

The good news is that whether it be long-life T8 fluorescent lamps or LEDs, there are lots of illumination choices to backlight your sign and deliver a product to your customer that will reduce their long-term costs.

This article was published in Sign & Digital Graphics magazine on December 21, 2016.